Don't assume it's worn out: Adjusting a

steering gear box

By Phil Lapin

The steering gearbox on Plymouths (and other MoPar brands) from the late 1930s up until the mid 1950s used a worm-and-roller gear system to provide steering capability. Although they worked well, over time a few problem areas on these gearboxes can develop.

I recently repaired and adjusted the gearbox on my 1942 Plymouth – and I learned a few things. Number ONE is that if you are having problems with yours, there may be simple fixes, rather than assuming the unit is “worn out”!

I recently repaired and adjusted the gearbox on my 1942 Plymouth – and I learned a few things. Number ONE is that if you are having problems with yours, there may be simple fixes, rather than assuming the unit is “worn out”!

Two common issues involve oil (lubricant) leaking, and also excessive play in the steering wheel.

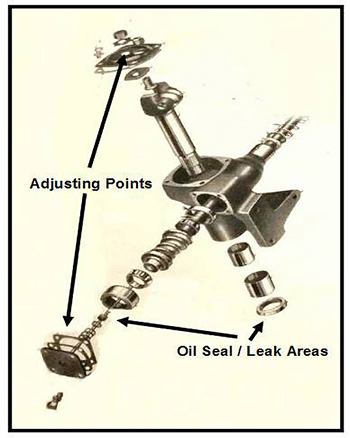

Click here or on the diagram at right for an image you can download and print.

Let me address oil issues first. There are two oil seals on these systems. One is on the “underside” of the box where the steering gear shaft exits. This seems to be the most common area of leakage. The other seal is inside the “end” of the steering assembly where the horn wire exits. This is a small seal around the tube that the horn wire passes through. Drips are messy, but wear inside the box due to loss of the lubricant is the real problem. In my car, the smaller internal seal on the end tube had completely failed. It looked to have been leather. I stamped out a new leather “washer” of the proper size and re-assembled the pieces after oiling the leather.

A common “fix” for the oil leaking out of the gearbox was to fill it with grease rather than heavy oil. NOT a good idea, as the grease will eventually be squeezed out of position - allowing for continued wear. A great fix recommended to me by club member (and owner of Elderly Auto Parts) Doug Crawford - comes from Australia! The Penrite company “down under” makes a special “Steering Box Lube” just for these early gearboxes. It is a jelly like grease formula which will slowly settle flat inside the gearbox, assuring continued lubrication - yet too thick to leak past the seals. It works! In the US, a company named “Restoration Supply” (www.restorationstuff.com) distributes it.

The other common area of concern is free play in the steering wheel. Linkage and bushings may cause this condition, BUT the problem may be simple adjustments that you can make – and adjustments are free!

There are two adjusting areas on the gearbox. Both can affect looseness. One is on the upper plate of the gearbox - next to the lube fill plug. There is a cap type locknut and star shaped lock plate visible. Removing the locknut reveals a slotted adjusting screw. It controls the contact between the two gears inside. It should be adjusted to where there is no free play between the gears - yet no binding.

The second adjustment is at the end cover of the box. Four bolts hold the cover on, and under the cover are thin shims. These shims adjust the spacing of the two bearings holding the worm gear in position. In my overhaul, I had to remove this cover to get at the seal. I was amazed at what just loosening the bolts did. The free play in the steering wheel increased drastically! So . . . removing shims progressively and re-tightening the cover can take much of the free play out of your steering.

Experimenting does not hurt. At the least, you are checking the easy fixes first.